Today, in the era of COVID-19 pandemic, supply chain resilience and responsiveness are significant to handle sudden discrepancies. Supply chain resilience is a company’s or an organization’s aptitude to steer unexpected supply chain interruptions with its prevailing capabilities.

Well, in other words, supply chain resilience is the capability to respond to difficulties by recovering from them without substantial impact on procedures. In business, supply chain management (SCM) is the management of the drift of goods and services.

Hence, organizations need to strengthen their supply chains so they can survive serious disruptions. This involves them building resilience – not just focusing mainly on managing risk.

Major Interpretations Of Supply Chain Resilience

Before just understanding the seven essential capacities of supply chain resilience, it is also important to know the interpretations of supply chain resilience.

1. Resilience in the sense of engineering resilience

The interpretation of resilience in the sense of engineering resilience prevailed for a long time. The potentials placed on managers come close to those positioned on engineers, who should respond quickly in the event of trouble as quickly as possible.

In the short term, a supply chain can be regarded as a comparatively inflexible system. The idea of determination of a supply chain that trails from engineering resilience, therefore, makes sense in short period. Though, this approach has its boundaries in the mid to long term.

2. Resilience in the sense of socio-ecological resilience

A supply chain is being interpreted as a social-ecological structure that is able to continuously adapt to external environmental conditions. This leads to a panarchical explanation of a supply chain allowing to scrutinize the communications of the supply chain with systems that function at other levels (e.g. society, political economy, planet Earth).

In disparity to engineering resilience, this is not construed as a system that needs to be alleviated in a fixed state but as a fluid system or a process that intermingles with the rest of the world.

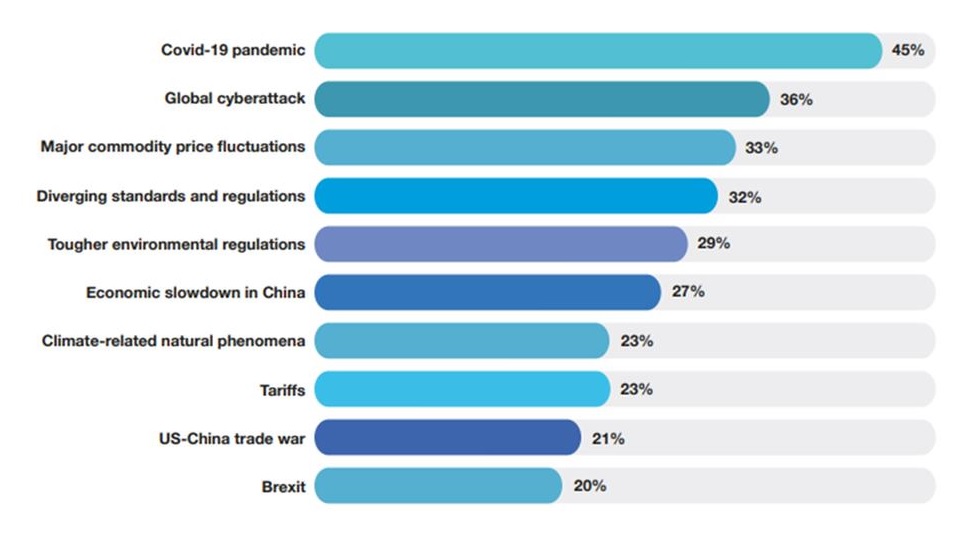

Aspects disrupting supply chains over the past three years -

In 2019, PWC commented on the importance of supply chain resilience, saying, “It’s not just about playing defense – it’s also about playing offense – finding competitive advantage by shaping a supply chain resilience strategy focused on disruption avoidance.”

Framework of Resilience

There are only seven ways in which a supply chain can fail. These are –

- The aptitude to acquire materials (maintain supply).

- The capacity to ship and/or transport products.

- The skill to interconnect.

- The capacity to renovate (interior manufacturing operations).

- The human resources (personnel) volume.

- The capacity to preserve financial drifts.

- The expertise to allocate products to customers including customers.

But the main enablers of a Supply Chain Resilience strategy are - People, Process and Technology.

People: Companies and businesses need plentiful manpower to complete the work. Therefore, look for individuals with current market knowledge, who can support the company to stay ahead of market movements. After that, structure your organization for accomplishment. You can make a commodity management team and a supplier relationship team.

Process: To handle the module shortages and desuetude, businesses need to strengthen their developments in 4 areas:? Forecasting, Inventory, Supplier relationships and sourcing and Market awareness.

Technology: Technology will help establishments complete the aforementioned processes more easily and precisely. Nowadays, the digital economy demands a new-fangled approach to manage the complete supply chain ecosystem. Businesses should invest in solutions that can be tailored to meet their individual supplies for better supply chain risk supervision.

When businesses finance in divergence, supply chain technologies, and other resilience dealings, there are numerous potential business benefits, counting:

- Minimized risk with a greater aptitude to invest in innovation and growth

- Enhanced productivity across the system

- Reduced jeopardy by allowing prominence into all operations across the system

To End With

Planning in advance with a strong supply chain resilience approach will help your company challenge any potential disruption. In order to understand more, professionals are opting for an online MBA in logistics and supply chain management for working professionals programmes.

East Bridge College’s MBA in Logistics & Supply Chain Management degree enhances your real-world capabilities, mainly in logistics and supply chain management. The degree is specifically planned for the busy working professionals and you can earn credit for your prior learning and experience as well.

Liked what you read? Share it and contact us for the MBA in Logistics & Supply Chain Management degree!

Written By : Brenda Martin